A self-loading concrete mixer mounted on a mobile chassis is a type of machine that allows the operator to load it with raw materials, like cement, aggregate and water, by itself. This eliminates the need for extra equipment or manual labor. Once it is loaded, it can be moved to the construction site and can be used to mix and distribute the concrete as needed.

Carmix self-loading concrete mixers have demonstrated their effectiveness in providing concrete supply to remote and challenging projects, such as in mountainous regions at high altitudes, constructing foundations for space telescopes, and building communication antenna bases on remote islands. Its low overall height also allows for easy access in tunnel construction without the need for additional equipment.

The military engages in a variety of construction projects such as creating and sustaining military bases, roads, bridges, airfields, and other vital infrastructures. They also partake in constructing and mending structures for accommodation, storage, and other purposes. Furthermore, they may provide aid in rebuilding and reconstructing areas that have been destroyed by war or natural disasters.

If we are to talk about more army focused construction needs, here are a few:

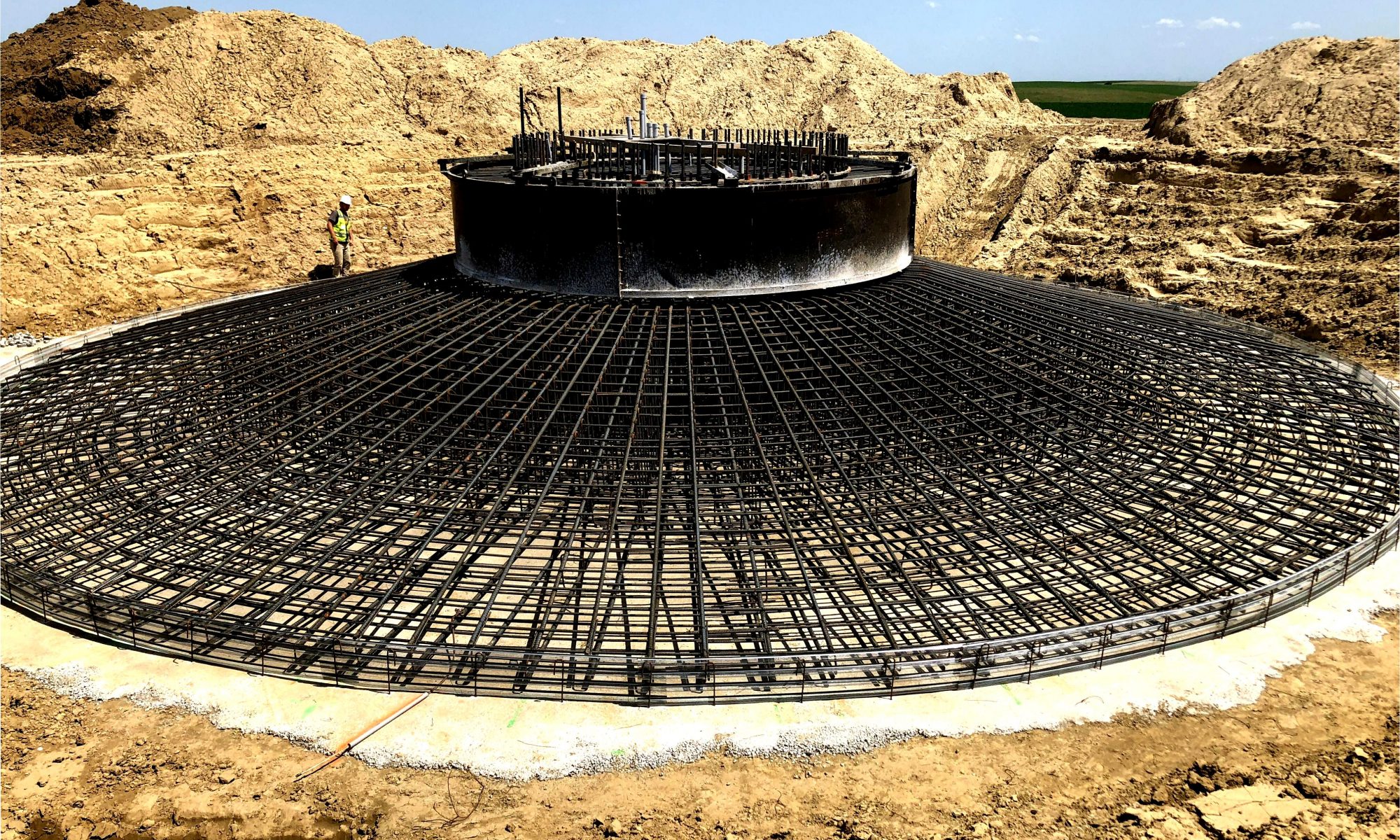

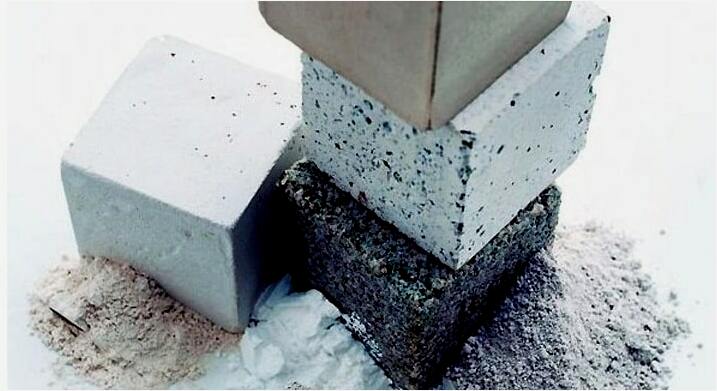

Military base infrastructure relies heavily on concrete for various construction projects, including the foundations, walls, and floors of buildings, as well as other structures. The robustness and durability of concrete make it a suitable material for military bases that require structures that can withstand harsh conditions and potential assaults. Additionally, concrete is used in the construction of bunkers, fortifications, and other protective structures on military bases. These structures are intended to safeguard personnel and equipment during combat operations.

The cost-effectiveness and availability of concrete make it a suitable option for large-scale military construction projects that need to be completed quickly and within budget. This material is highly durable, which is important for facilities that are critical to military operations such as airfields, helicopter pads, and runways. The smooth and level surface of concrete runways allows for safe and efficient aircraft landing and takeoff, while the durability of concrete ensures that the runway will remain operational even under heavy use. The construction of durable heavy vehicle parking pads is also crucial for military use, specially designed concrete surfaces that provide a stable and durable platform for heavy vehicles such as tanks, armored personnel carriers, and other military vehicles. These pads are typically constructed with reinforced concrete and are designed to withstand the heavy weight and constant movement of military vehicles. They are often found at military bases, training facilities, and deployment locations and are designed to drain water away from the vehicles, to prevent erosion and rusting.

Concrete is essential for the construction of military-specific objects, as it provides durability and strength to withstand harsh conditions and hazards. Additionally, concrete pads are designed to resist fire, chemical spills, and other potential hazards in a military environment.

In summary, some of the key military-specific objects that require concrete for their construction include:

- Building bunkers and fortifications for protection against heavy artillery and bomb blasts.

- Constructing runways and airfields for military aircraft.

- Building safe and secure housing units for military personnel.

- Constructing bridges and roadways that can support heavy military vehicles and equipment.

- Building underground storage facilities for ammunition and other military equipment.

- Constructing training facilities such as shooting ranges.

Carmix self-loading concrete mixers can be a tactical advantage in military operations as they can provide on-site concrete mixing and delivery, ensuring a steady supply of concrete for the construction of these military-specific objects.

There are several obstacles that military construction projects often face, including but not limited to:

- Difficulty in accessing and transporting materials and equipment to remote or hard-to-reach areas.

- Adverse weather conditions such as high winds, extreme temperatures, and heavy rainfall that can pose challenges for concrete construction.

- Security concerns that limit access to the site and transport of materials and equipment.

- Limited resources, including water and power, which can make it challenging to mix and pour concrete.

- Shortage of workforce that may impede the completion of construction projects in a timely manner.

- The need to consider cultural and environmental factors in areas where the military sites are located.

When it comes to constructing structures for military needs, there can be difficulties in obtaining and transporting the necessary concrete. One solution is to use precast concrete, which is made off-site and then transported to the construction location. However, the main challenge with this method is the transportation of the precast concrete. Using a Carmix self-loading concrete mixer can provide a solution as it allows for on-site production of the necessary grade of concrete in sufficient amounts. This can lead to significant savings in both time and resources, as well as minimizing the need for transportation. Such structures that can be built using precast concrete and carmix self-loading concrete mixer include: barracks, housing units, bunkers, shelters, blast walls, aircraft hangars, maintenance facilities, guard towers, observation posts, ammunition storage facilities, fuel storage tanks, parking garages, vehicle storage facilities, bridges, and culverts.

A self-loading concrete mixer is an ideal equipment for military operations as it offers versatility, efficiency and ease of use. The machine can quickly and easily mix and dispense concrete, reducing the need for manual labor and the risk of injuries. With its self-loading feature, it can load raw materials by itself, further reducing manual labor. It can be easily transported to different locations, making it suitable for use in remote or hard-to-reach areas. In conclusion, a self-loading concrete mixer is an efficient and safe tool for military construction and repair projects in the field.

Time constraints are a significant challenge for military construction projects. Carmix self-loading concrete mixers provide a tactical advantage by being able to mix their first 4 cubic yards of concrete just 20 minutes after arriving at a construction site. This eliminates the need for lengthy installation and setup typically required by stationary batching plants. Additionally, Carmix mixers only require one machine and one operator, making it a highly efficient option for concrete production in time-sensitive situations. With experience working with various armed forces across the world and the ability to produce concrete quickly and efficiently in any weather or climate conditions, Carmix self-loading concrete mixers are a valuable asset for military operations.